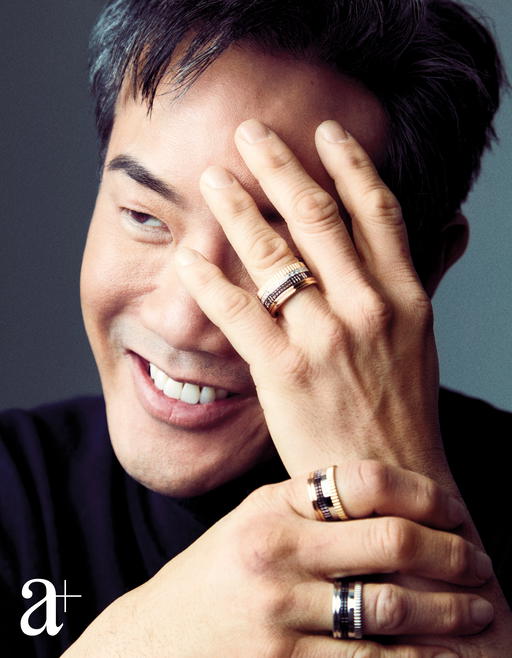

Many hands make light work. As adolescents, Daphne Lim and her two sisters would sort and stick laminate samples their father lugged home into catalogues. Watching him struggle to get his business off the ground made them eager to chip in.

Her father Richard had left a family business after two decades to start his own. Going back to the drawing board at 54 did not faze him. In 2002, he launched EDL to sell high-pressure laminates, a decorative surfacing material used in interior design and construction.

EDL is an amalgamation of the first letters of his daughters’ names—Daphne, Eleanor, and Desiree—and the first letter of their family name. The company began in Sungei Kadut with seven staff, which included him and his wife.

Growing up in an average-income family, Lim worked several part-time jobs while studying at Temasek Polytechnic. She had been contemplating enrolling in university after graduation when her father mentioned he needed help at EDL. Not that she felt obliged to come onboard, she clarifies. “My sisters and I have watched him work in this field since we were children, so it was almost natural for me to follow in his footsteps. There was no pressure from him. I wanted to give it a go to see if I would enjoy it.”

Imaginably, all eyes were on the greenhorn. “I was working with people who had a lot of industry experience, so they were like, ‘What is this young girl doing here?’” she recounts. Despite the multiple hoops she had to jump through, she put her nose to the grindstone. She had to learn the ropes and she had to learn them fast.

Her first job at the company was in sales. The Internet wasn’t what it was today so she would spend hours scouring Yellow Pages for design companies and making cold calls. “I needed to show them our catalogues. Whenever I secured a meeting, I’d lug all my barang-barang to their office. Some companies didn’t like working with new brands and would go, ‘What brand is this?’”

Lim was typically only given five to 10 minutes to present EDL’s unique selling proposition. “I had to convince them to give our products a chance. I did this every day for over 10 years.”

DIVERSIFYING OPTIONS

Today, the 37-year-old is Director at EDL, which has grown to 200 employees. Starting at the bottom meant she painstakingly acquired all the integral skills necessary for her position. “Nobody would buy into it if I had come in as a manager, but I went door-to-door and did everything myself for a long time,” she says. “I understand the struggles our salespeople face because I’ve gone through them.”

While laminates remain EDL’s core business, the company has diversified its range of products to better meet customer needs. A surge in customers seeking sleek worktops in wood grain and stone finishes led to the introduction of Compact, a range of thicker versions of laminates for worktop solutions.

It has also introduced Module, a collection of high-integrity, non-flammable melamine boards from Japan, to reduce hacking. The wall-cladding material can be applied directly over tiles.

Module is distributed by EDL, while Compact is distributed, supplied and installed with dedicated cutting and measuring equipment. It also carries knobs and handles by Spanish brand Viefe to offer customers more options.

Then there is Aptico, an anti-fingerprint matte laminate. “Glossy finishes used to be popular, but people now want matte everything: lipstick, cars, and home fixtures. The problem is that matte materials don’t always conceal fingerprints, so we aimed to fill a void in the market. We were the first in Singapore to do so with this material.”

Traditionally a B2B company that works with architects, product designers, and interior designers, EDL is now also growing its B2C market. It was an incidental expansion, Lim says. “We weren’t actively reaching out to homeowners, but thanks to social media, they started dropping by our office to check out our large sheets and ask about new products,”

she explains.

Given that homeowners are increasingly house-proud and curious about the ins and outs of the construction of their homes, the company decided it was necessary to accommodate them with a modest gallery in its former office and warehouse. “We carved out a space on level three to let them experience the brand, which led to even more walk-ins. Interior designers would even bring their clients along to experience the materials.”

Plans to move to a larger office warehouse—the third “home” since EDL was founded—were set in motion for 2020. The pandemic, however, threw a wrench into the works, so the project dragged on for four years instead of taking what was supposed to be 18 months to complete.

It didn’t help that the contractor’s company went bust. “No one wants to take over a job that is 80 percent complete, right? On top of that, our then-landlord was waiting for us to leave since our lease had expired, but we needed somewhere to store our machines. There was a lot of uncertainty.”

Many sleepless nights resulted from the trepidation-filled period. Eventually, they found someone to do the job. “Yes, we had to pay a premium price, but at least it resolved the issue.”

CAPTURING MARKETS

EDL’s new headquarters opened its doors at 17 Woodlands Terrace this year. It sits in a compound measuring 5,110sqm and is made up of an office, production workshop, and gallery, with the capacious showroom designed to take visitors on a journey through several key features. For instance, visitors can examine laminates under different lighting colour temperatures.

Additionally, an on-site QR code leads to the company’s microsite that Lim and her team developed after observing that most visitors prefer to browse unassisted. “They don’t want people following them around, so the site helps them find things themselves as they walk around the space.”

The technology also provides thematic suggestions and minimises human error, Lim explains. “Much as we hope it doesn’t happen, staff don’t always provide consistent messaging. With the microsite, visitors get accurate information they might have otherwise missed.”

It also presents pictures of the laminates in completed projects. “This is what clients and designers want to see the most,” Lim says. “They become more equipped to ask themselves, ‘Is this really what we want?”

EDL has since expanded into Malaysia, Thailand, and Indonesia. After Singapore, Thailand is Lim’s second-largest customer base, possibly due to similar tastes in design. In Malaysia, the company has an office in Kuala Lumpur and another in Penang. Although small, the latter has great potential, Lim adds.

Because EDL just set up shop in Indonesia, its efforts are now focused on growing the market. The company is familiar with its intricacies. “We have exhibited at trade shows there for five years, so we know the market well. We always see a lot of interest in our products when we are there. People would ask, ‘When are you coming in?’”

EDL took its time to because it wanted to perfect its supply chain.

“We need ready stock in this fast-moving industry in order for clients to have confidence in using our products. Usually, when they make project specifications, they expect us to have ready supplies. We can have good products, but without ready stock, it’s difficult to succeed.”

Daphne Lim on industry prerequisites

The company’s products are manufactured in Japan, Korea, and Italy, and then shipped to Singapore before being exported to Malaysia, Thailand, and Indonesia. “We must reorganise and pack the goods before shipping them, which was why we really needed the new space,” Lim sums up.

BUILDING A LEGACY

In Lim’s opinion, connecting with people is her greatest strength. Developing an open communication culture and continuously collecting employee feedback is something she finds fulfilling. As it stands, a company needs employee buy-in for ideas so everyone can work towards a common goal.

Her father, as CEO, is still heavily involved in the business, but is increasingly leaving major decisions to Lim and her sisters—Eleanor is Marketing Director and Desiree is Marketing Manager. He doesn’t shy away from newfangled concepts. “He doesn’t know how to use social media, but understands its importance, so he has left building the company’s image to us ,” Lim says.

“Here’s a case in point: a gallery isn’t money-making, right? People can experience the brand, but it doesn’t guarantee a sale. But when we pitched the idea, he said, ‘Okay, let’s try’. This surprised us.”

As a way of ensuring his daughters are competent in continuing the family legacy, he has them shadow him closely. “He wants us to understand why he makes certain decisions and why he does things the way he does,” Lim explains. “Knowing what product to stock, how to stock it, how much to stock, and what the bestselling colours are is a skill. Knowing these things reduces disruptions to your operations.”

The family is emphatically close. Even though she is around her parents all day in the office, Lim continues to spend time with them after work. She moved back in with them after the birth of her son two years ago.

Lim and her sisters still sort and stick (to) things, but now, instead of laminates, they are in the form of weekly dinner plans. There are no ground rules for conversations at home—nobody minds if the topic revolves around work. “Work is a huge part of our lives, so if it is necessary, we’ll talk about it. Otherwise, we’re pretty chill and can switch off.”

Photography Stefan Khoo

Styling & art direction Chia Wei Choong

Hair Aung Apichai / Artistry Studios, using Kevin.Murphy

Makeup Wee Ming, using Chanel Beauty

Photography assistant Alif