Christine Hutter’s journey into the world of horology is as unique as the watchmaking brand she leads. While most CEOs are trained in the boardroom, she is a trained watchmaker who spent three years restoring and crafting timepieces by hand as part of a three-year apprenticeship. This set the stage for her future endeavours, culminating in her discovery of the Moritz Grossmann legacy in Glashütte, Germany’s historic watchmaking centre.

Inspired by his 19th-century contributions to horology and his social impact, Hutter revived his name and founded Grossmann Uhren GmbH in November 2008. While it was challenging to establish a new brand in a field dominated by heritage brands, Hutter’s commitment to producing watches of unmatched quality has made Moritz Grossmann a symbol of Saxon watchmaking excellence.

What makes Saxon watchmaking unique in the industry?

It is renowned for its technical expertise, aesthetic approach, and attention to detail. Watchmaking in Glashütte has always differed from other watchmaking centres. Pioneers such as Moritz Grossmann and Adolph Lange studied movements in major watchmaking cities before developing a distinctive “Glashütte watch” characterised by elements like the three-quarter plate and Glashütte click wheel. These watches were designed to be practical, easy to manufacture, and to retain their value for a long time.

To this day, Glashütte watchmakers continue to be inspired by such historical values, drawing upon their rich heritage to create beautiful watches that build upon the proven designs of the old masters. In our timepieces, you will still find the large wheel bridge, the Glashütte stopwork, the three-band snailing on the ratchet wheel, and a hand engraved balance cock with Grossmann’s regulating screw. Each watch and individual component is still hand-finished, as it was in the past.

Moritz Grossmann’s legacy as an eminent watchmaker from the 19th century inspires us. We still use many of his innovations in our movements. In Grossmann’s lifetime, he was praised for the fine hands on his pocket watches and measuring instruments. Since we are deeply committed to this tradition, all of our hands are handmade. Few brands in the world can claim such a level of dedication. We emphasise craftsmanship when completing our movements.

How does Moritz Grossmann plan to continue innovating with unconventional materials and techniques in future designs?

In addition to developing new innovations for our movements, we have also revived historical dial techniques, bringing them into the modern age. For example, we reintroduced a technique called tremblage. It involves engraving a German silver dial by hand, using a variety of burins. During the process, these tools are moved across the metal in a trembling motion, hence the name Tremblant, which means “to tremble” in French. Looking ahead, we will continue to explore new movement innovations and design approaches to think outside the box and push the boundaries of our craft. Our primary focus, however, remains resolute: to maintain a high level of quality. Whether it’s innovation, quality, or craftsmanship, we never compromise. We have embraced Grossmann’s credo of producing a mechanically perfect watch while keeping it simple. This brand essence has guided us as we’ve built Grossmann watches step by step, continually expanding with new design approaches and technical innovations.

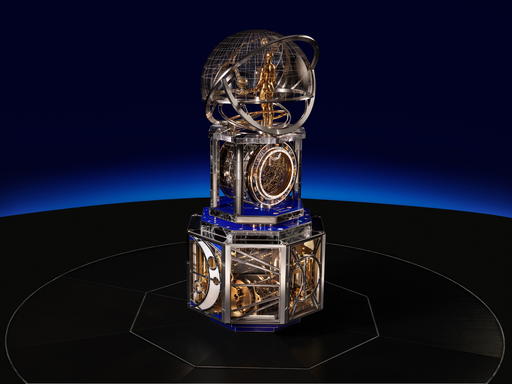

What was the most challenging part of creating the Moritz Grossmann Hamatic Astral Sincere Platinum Jubilee Edition?

This was the first time we had crafted this type of dial. It features goldstone, which evokes an aura of eternity resembling a shimmering universe. The mesmerising effect is achieved through the art of glassmaking and the skilled application of goldstone. The manufacturing process dates back to the early 17th century in Venice, where it was discovered by chance. The goldstone is created by melting glass with copper in a flame. Temperature control is used to prevent overheating, which leads to the forming of crystalline clusters of copper that stick to the glass like glitter. Goldstone is ideal for crafting dials because it can be cut, polished, and cast.

For this extraordinary timepiece, we also incorporated our exclusive Hamatic self-winding movement. The calibre 106.0 is one of our most sophisticated and innovative movements. It draws inspiration from 18th-century automatic watchmaking, where a hammer-shaped pendulum harnessed kinetic energy. This advanced movement, featuring an open-frame design visible through a sapphire crystal display back, ensures high energy efficiency and consistent winding power for precision and reliability.

Our primary focus, however, remains resolute: to maintain a high level of quality. Whether it’s innovation, quality, or craftsmanship, we never compromise.

Christine Hutter

The field of watchmaking has traditionally been dominated by men. What significance does women’s leadership have in this field?

It is encouraging to see more women taking on prominent roles in a highly technical field like watchmaking. This trend is also evident in other technically oriented sectors. In my view, it’s beneficial to have a balance between women and men in a company. However, success ultimately depends on ability, expertise, and leadership skills, regardless of gender.

What has been the most challenging aspect of your role as CEO?

One of the biggest challenges was establishing an independent brand in a well-established market, which required a significant investment in brand visibility and building a retailer network. I am particularly proud of my team. Since 2008, we have developed 15 calibres and introduced over 20 technical innovations in movements and dial-finishing techniques. Another challenge was setting up a modern facility with state of-the-art machinery and an in-house production line. In just five years, we have successfully built a production facility from the ground up, with 90 percent of the construction of movements, prototyping, finishing, and assembly done in-house