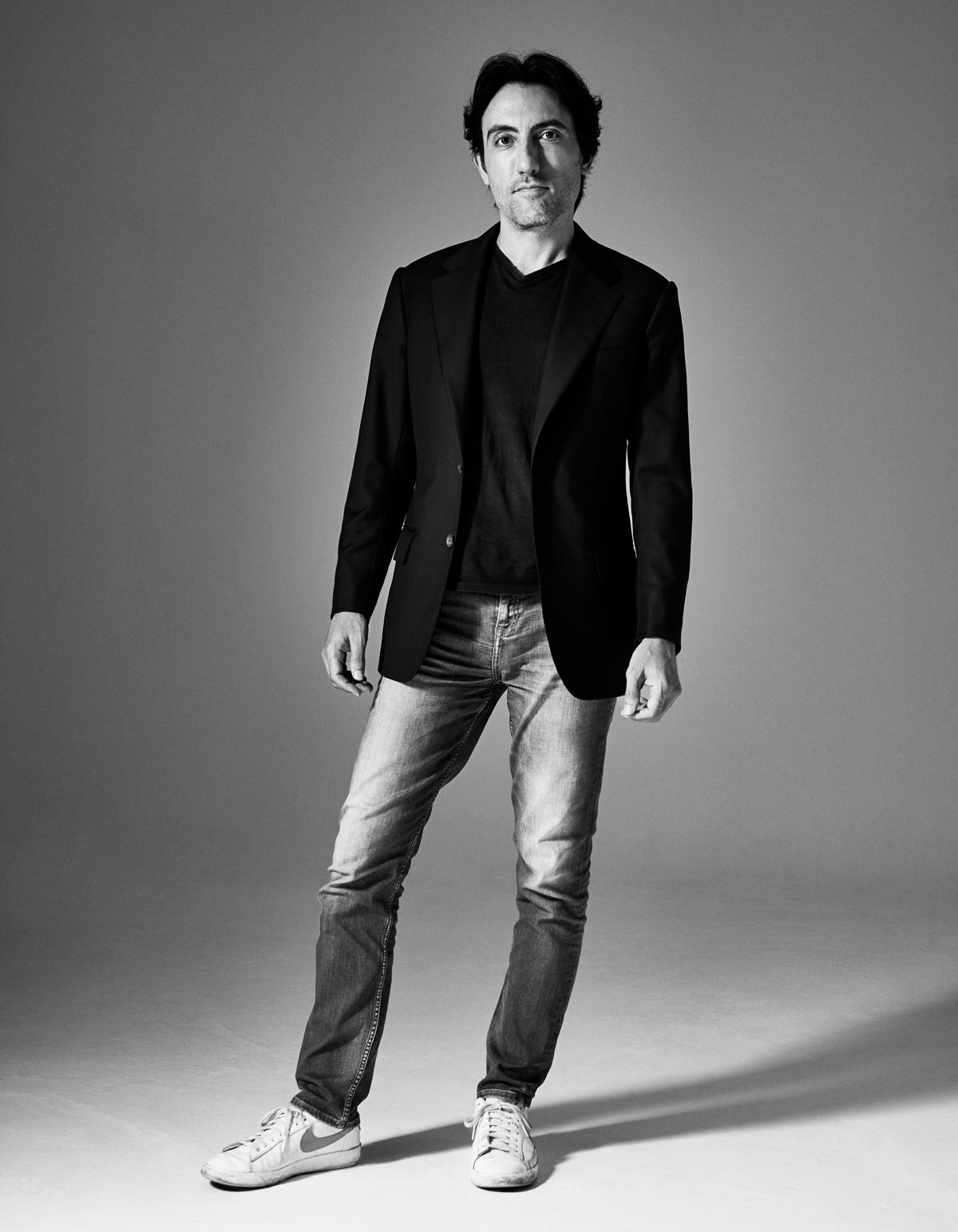

Born in Milan, Italy, Manuel Bossi is no stranger to the chickpea, an integral part of traditional Italian dishes.

Today, despite living away from home, his connection with this humble legume has gotten stronger, thanks to his work as the CEO of plant-based nutrition company Growthwell Foods.

The Singapore-based firm is set to launch CHICK’P, a milk made from chickpeas, by the end of this year. The imminent launch comes amid the ever-growing alternative protein movement, backed by studies showing that the manufacturing process for plant-based milks generate significantly lesser greenhouse gas emissions compared to dairy milk.

Bossi points out that its new R&D and manufacturing facility at the JTC Foodhub @ Senoko will also be exploring ways to replace conventional milk in dairy products like yogurt and ice cream with the chickpea.

But what about naysayers who argue that plant-based alternatives aren’t necessarily more sustainable?

“You need to take such claims with a pinch of salt. Why? Because companies like ours are a threat to the meat and milk industries, which aren’t going to just sit there and do nothing as the alternative protein market grows 15 to 20 per cent every year,” he says.

Findings that plant-based foods have a smaller environmental footprint, he says, undoubtedly hold water because there are fewer steps in the production process. “A kilogram of beef requires up to 25,000 litres of water and about 25kg of animal feed, often made using soy, to produce,” he explains. “We take that 25kg of soy in this equation and turn it into something edible for humans. It’s more efficient and results in less wastage.”

Regarding the apprehension that some have over alternative proteins being processed foods, Bossi contends that people often misunderstand the term “processed”. What it ultimately means, he argues, is that something has been transformed from one state to the other. Flour, for example, can be considered a processed food because it is created through milling grains. But hardly anyone would label the ingredient as unhealthy.

“Processing just means transformation, and transformation is not necessarily bad. We need to ensure what goes into the process is of the right quality. You also want to make sure that that your process is as simple and clean as possible,” he says. For example, using only temperature, water and pressure, Growthwell Foods’ High Moisture Extrusion technology allows for more realistic textures and processes for its products.

It is crucial, Bossi acknowledges, that alternative protein companies get two things right before consumers bite. “You need to have a tasty product and price it right because people will not buy alternative protein products if they cost twice or thrice more than conventional sources of protein,” he says.

As for the matter of taste, Bossi is confident that things will only get better. He points out that the earliest samples of soy-based milk tasted of nothing but soy. These days, however, rapid technological advancements have resulted in more neutral-tasting, affordably priced products.

While the alternative protein market is still in its nascent stages, Bossi is quietly confident that it is only a matter of time before such foods become a staple. “Alternative proteins currently represent just 1 per cent of the total protein market,” he says. “That is a tremendous growth opportunity.”

Videography: Belle Chew

Photography: Mun Kong

Producer: Cara Yap

Styling: Chia Wei Choong

Hair & Makeup: Rick Yang/Artistry, assisted by Alycia Tan, using Shiseido and Keune